The Ford 4000 tractor is a popular model that has been used in agriculture for many years. If you’re looking for information about the clutch disc for the Ford 4000 tractor, it’s important to consider that specifications and availability may vary depending on the tractor’s year of manufacture and any modifications that may have been made to it over time.

Ford 4000 tractor clutch plate selection

Size and Specifications

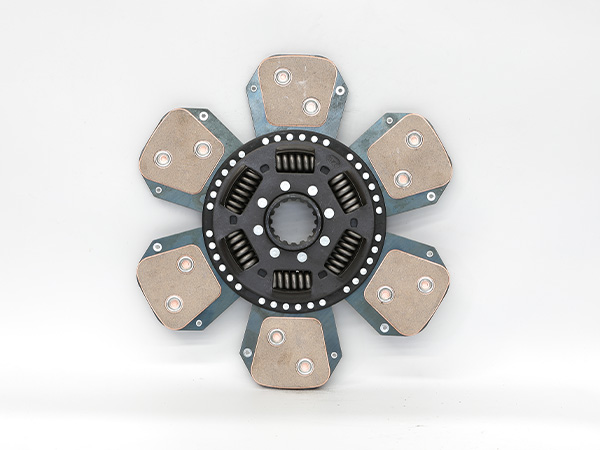

The clutch disc size and specifications may vary, so it’s crucial to know the exact model year and variant of the Ford 4000 tractor you have. Tractor parts suppliers and manufacturers provide specifications for their products, and you should match these to the requirements of your specific tractor.

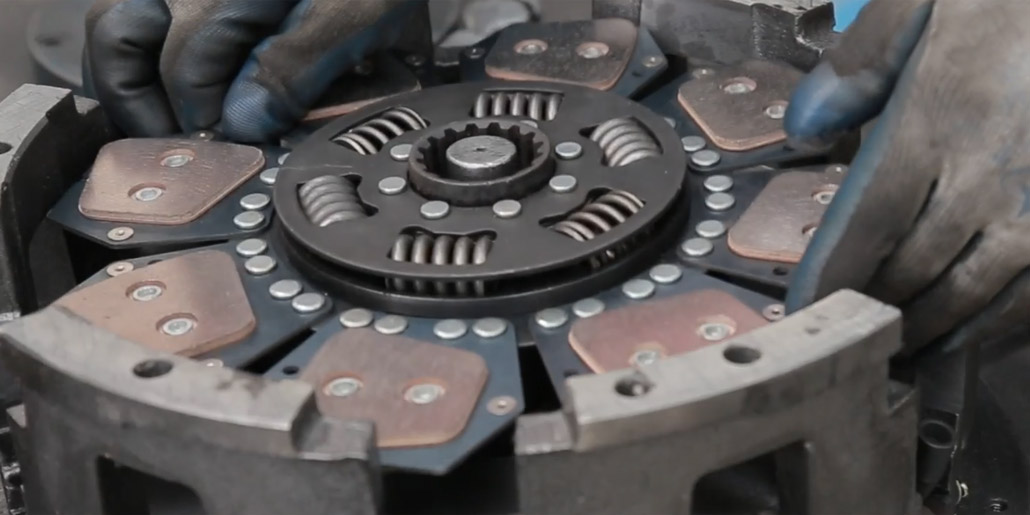

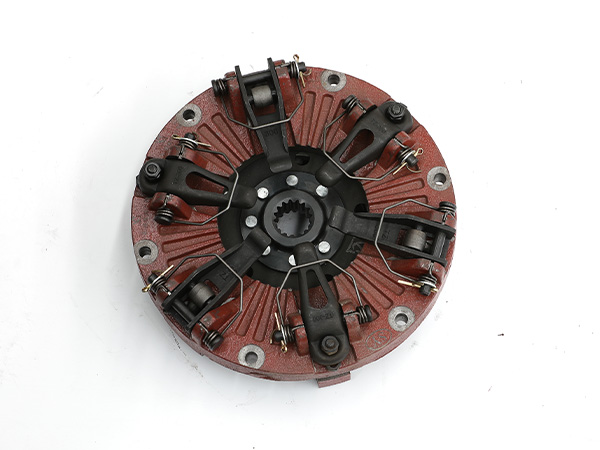

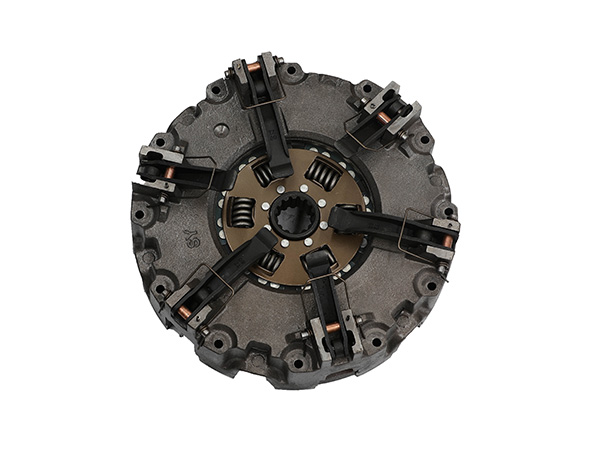

Material and Construction

Clutch discs are typically made of friction material, and the quality of this material can impact the overall performance and longevity of the clutch. Some clutch discs may have specific features, such as a spring center or a solid hub. Ensure that the replacement clutch disc matches the original specifications.

Purchase from Reputable Suppliers

When looking for a replacement clutch disc, it’s advisable to purchase from reputable tractor parts suppliers or dealers. They often have knowledgeable staff who can guide you in selecting the right part based on your tractor’s specifications.

About tractor clutch disc repair

Precautions for the replacement of tractor clutch friction discs

Tractor clutch friction disc replacement

What are the procedures for replacing tractor clutch disc?

OEM vs. Aftermarket Parts

Original Equipment Manufacturer (OEM) parts are produced by the same manufacturer that built the original parts for the tractor. Aftermarket parts are produced by third-party manufacturers. Both can be suitable, but it’s important to ensure that aftermarket parts meet or exceed the specifications of the OEM parts.

Consult the Manual

The tractor’s manual or service guide should provide details on the clutch specifications, including the recommended replacement parts. If you don’t have the manual, you may be able to find it online or obtain a copy from the tractor manufacturer.

Professional Advice

If you are uncertain about the specific clutch disc for your Ford 4000 tractor, consider consulting with a qualified mechanic or contacting the tractor manufacturer for guidance.

Remember that accurate information about the clutch disc for your Ford 4000 tractor will depend on the tractor’s specific model year and any modifications made to it. Always refer to the tractor’s manual and seek advice from reputable sources when purchasing replacement parts.