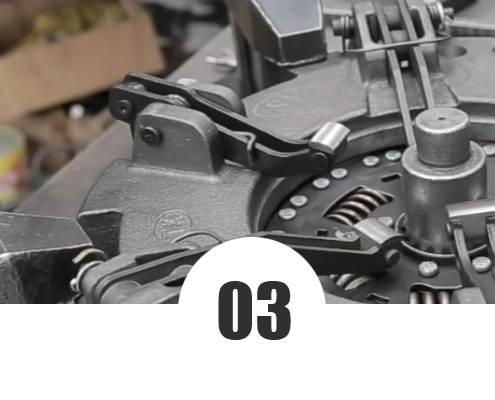

Tractor Clutch

The tractor clutch is installed between the engine and the gearbox, and its main function is to interrupt the transmission of power when necessary to ensure that the tractor starts smoothly; to ensure the smooth operation of the driveline when shifting; to limit the maximum torque that the driveline can bear to prevent drive train overloaded.

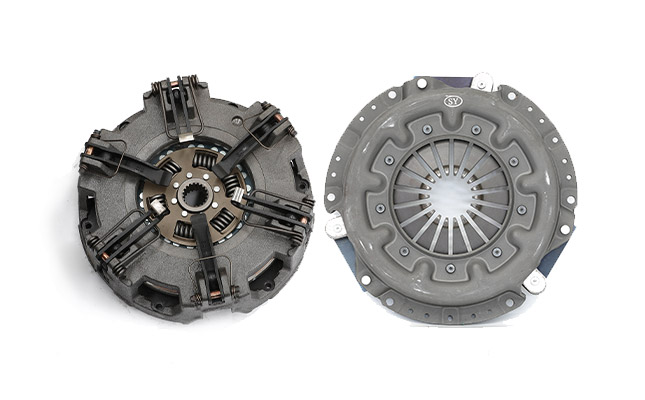

Tractor Clutch Kit

The tractor clutch kit is an indispensable part of the tractor, its main function is to transmit and cut off the power output, and prevent the parts from being damaged when the transmission system and the power output device are overloaded. A good clutch makes it easier and smoother to start the tractor without wobbling. Gear shifting and acceleration will be greatly improved, and clutch clearance will be reduced for a comfortable driving experience.

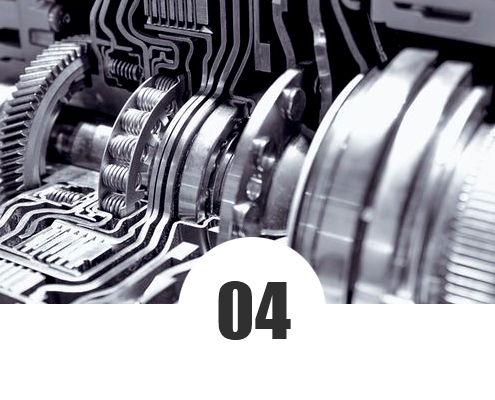

Tractor Clutch Disc

Tractor clutch plate is a composite material with friction as its main function and structural performance requirements. Tractor clutch plate materials are mainly made of asbestos-based, copper-based powder metallurgy and other materials, produced according to international standards, and the product quality is superior.

Clutch Spare Parts

Tractor clutch repair kits as universal parts, different sizes can meet all requirements of clutch kits. We have tractor clutch repair kit for 9 inch tractor clutch kits,10 inch tractor clutch kits,11 inch tractor clutch kits ,12 inch tractor clutch kits ,13 inch tractor clutch kits,14 inch tractor clutch kits,15 inch tractor clutch kits ,etc

Friction Disc

Our multi-model friction discs are widely used in agricultural machinery and construction machinery. The friction disc can work normally under high load and high temperature, with stable performance and wear resistance, low vibration and low noise.

What are the applications of tractor clutch kits?

NewsA tractor clutch kit is a set of components designed to replace or upgrade the clutch system in a tractor. The clutch is a critical part of a tractor’s drivetrain, responsible for engaging and disengaging power from the engine to the transmission, allowing the tractor to start, stop, and change gears smoothly. How a tractor […]

What are the materials of clutch friction disc?

NewsThe friction disc material used in clutches plays a crucial role in the performance, durability, and reliability of the clutch system. Various materials are used for friction discs, each offering different properties and suitability for specific applications. Clutch Friction Disc Materials Organic: Organic friction disc materials are composed of non-metallic materials such as cellulose, aramid […]

What are the differences between single-acting clutches and double-acting clutches?

NewsSingle-acting clutches and double-acting clutches differ primarily in their design and operation. Here are the key differences between the two: Number of Friction Surfaces: Single-Acting Clutch: Utilizes only one friction surface for engaging and disengaging the clutch. Double-Acting Clutch: Features two friction surfaces for engaging and disengaging the clutch. Engagement Mechanism: Single-Acting Clutch: Typically engaged […]