1.clutch pedal free stroke adjustment

In order to ensure the normal work of the clutch, the clearance between the end of the clutch release lever and the end of the thrust bearing of the loose sliding sleeve assembly * is kept in the range of (2.5±0.5) ㎜, corresponding to the free stroke of the clutch pedal is 20㎜ – 30㎜. In the process of use, due to the constant wear of the clutch friction plate, the pressure plate moves forward, the gap is gradually reduced, or even disappear, therefore, the * regular check. Clutch pedal free stroke adjustment method has the following two.

(1) External adjustment: loosen the lock nut on the pull rod, remove the connecting pin, screw out the adjusting fork, so that the pedal free stroke reaches 20㎜ – 30㎜, and then through the connecting pin, screw the locking nut.

(2) internal adjustment: remove the opening pin on the adjusting nut from the front check hole on the left side of the clutch housing, screw out the adjusting nut, so that the clearance between the end of the lever (three-claw screw) and the end of the sliding sleeve thrust bearing reaches (2.5±0.5) ㎜, and then put the new opening pin into the lock. When using this method to adjust, ensure that the three loose lever end in the same vertical plane, with thickness gauge check, the error should not be greater than 0.3㎜.

2. Clutch separation stroke adjustment

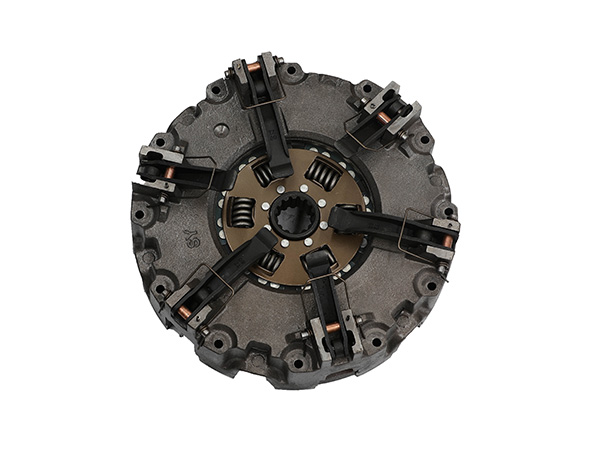

In order to ensure the main clutch and separation of the power output of the clutch thoroughly, * make three block pin end face and the supporting bolt screw ring (9) end clearance in (2.25 + / – 0.5 ㎜), too big or too small, can cause the main clutch and power output, respectively, the separation of the clutch is not complete, therefore, should be regularly check and adjust when necessary.

When adjusting, screw the three supporting bolts to the end face of the corresponding three file pins, and then return the supporting bolts to the 9 card slots respectively (you can hear 9 sound), this gap is the value specified above.

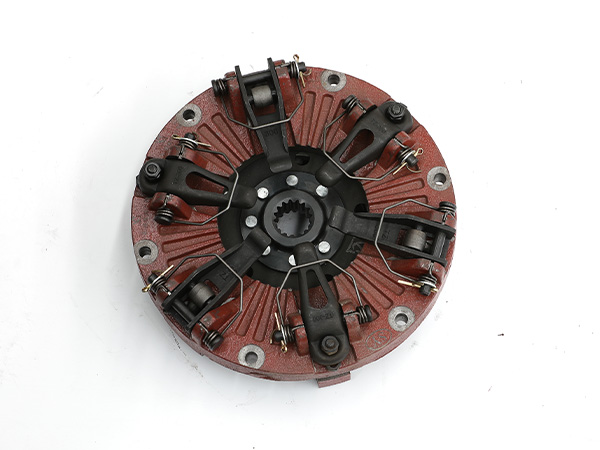

3. Adjustment of release lever position

When re-installing the clutch disc assembly, * make the distance from the end of the lever to the end of the hub of the rear driven disc assembly 40 0-0.3mm loose; With butterfly spring this value is 42.5㎜.

Note: do not remove the interlocking lever when adjusting the free travel of the clutch pedal.

Luoyang Shengyuan Clutch Co., Ltd. is located in luoyang, the ancient capital of China’s heavy industry city in 119. since its establishment, it has been committed to the development and production of tractor clutch assembly and clutch friction plate.

Company has a full set of clutch production equipment, as well as the domestic industry advanced tractor clutch assembly comprehensive testing machine, durability testing machine, disc spring testing machine based on the comprehensive testing assembly components and assemblies, etc. The whole process control, effective guarantee for the comprehensive performance of the clutch, make our company product quality is in domestic * level. With the continuous development and growth of the enterprise, Shengyuan Clutch company has passed the ISO9001:2015 quality management system certification, and has a complete quality assurance system in quality management assurance, and has been effectively implemented and implemented. Deeply the quality of products to improve the enterprise reputation, and expand the market share of the important role, as momentum of enterprise management, the company all staff with unremitting efforts to make the quality management system for a long time lasting, normal and effective operation, continuously improve product quality, and with excellent quality to win the majority of customers support and trust.