The price of a tractor clutch can vary widely based on several factors, including the make and model of the tractor, the specific type of clutch, and whether it’s an original equipment manufacturer (OEM) part or an aftermarket replacement. Additionally, prices may vary depending on the region, availability, and seller.

Here are some general considerations regarding tractor clutch prices

OEM vs. Aftermarket

OEM tractor clutches, produced by the same manufacturer as the tractor, tend to be more expensive. Aftermarket clutches, manufactured by third-party companies, are often more affordable. The choice between OEM and aftermarket may depend on factors such as warranty, brand preference, and budget.

Tractor Model and Make

The specific tractor model and make significantly influence the price. Larger or more specialized tractors may have more complex and expensive clutches.

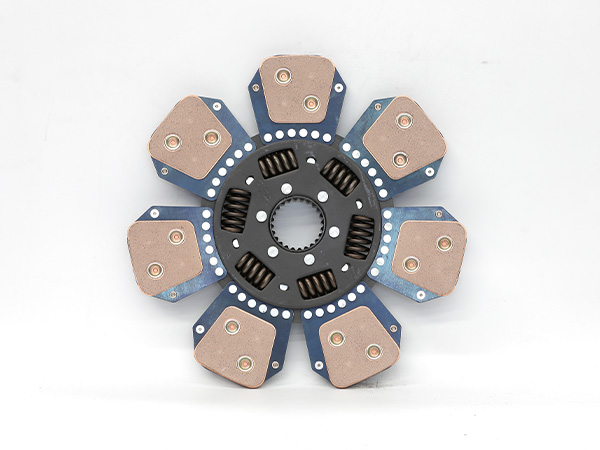

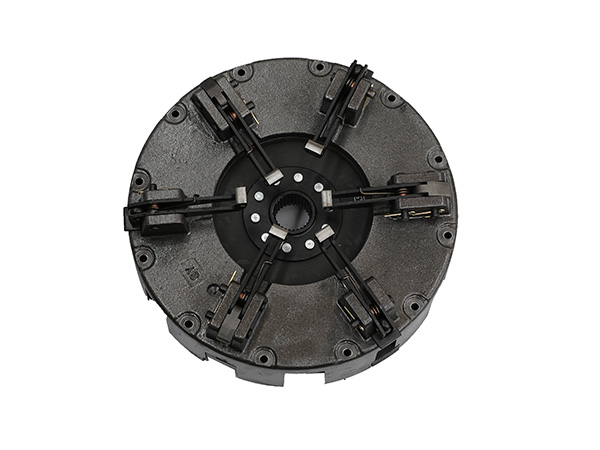

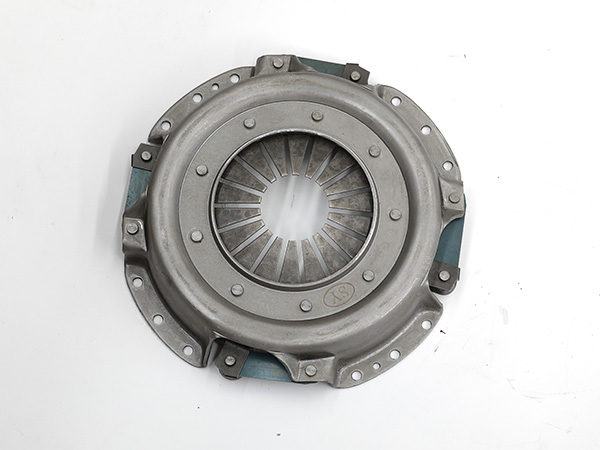

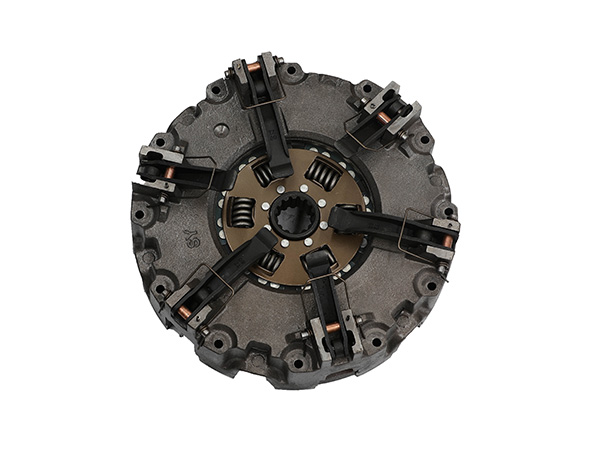

Type of Clutch

Tractors can have different types of clutches, such as dry clutches or wet clutches. The type of clutch required for your tractor will impact the price.

Kit vs. Individual Components

Some clutch replacements come as kits, including pressure plates, discs, bearings, and other components. Others may be sold as individual components. Kits may offer a cost savings compared to buying each part separately.

Brand and Quality

The brand and quality of the clutch can affect the price. Reputable brands known for producing durable and reliable tractor parts may have higher prices.

Local Dealers vs. Online Sellers

Prices can also vary between local tractor dealerships and online sellers. It’s worth checking multiple sources to compare prices and find the best deal.

Availability and Demand

If a particular tractor clutch is in high demand or has limited availability, it may affect the price. Consider market conditions and availability when determining the cost.

Installation Costs

Keep in mind that the cost of the clutch itself is only part of the overall expense. Installation costs, which may include labor charges, can also contribute to the total expenditure.

To get an accurate price for a tractor clutch for your specific make and model, it’s recommended to contact tractor dealerships, authorized parts distributors, or reputable online retailers. Provide details about your tractor, including the model and year, to get quotes tailored to your needs. Additionally, inquire about any warranties or guarantees that come with the clutch to ensure you’re making a reliable purchase.