Introduction

In the world of agriculture and heavy machinery, tractors stand as essential workhorses. Central to their performance is a mechanical marvel known as the tractor clutch. This critical component enables seamless power transfer between the engine and transmission, ensuring smooth operation, efficiency, and control. In this technical exploration, we delve into the intricate world of tractor clutches, unraveling their structure, functions, and maintenance.

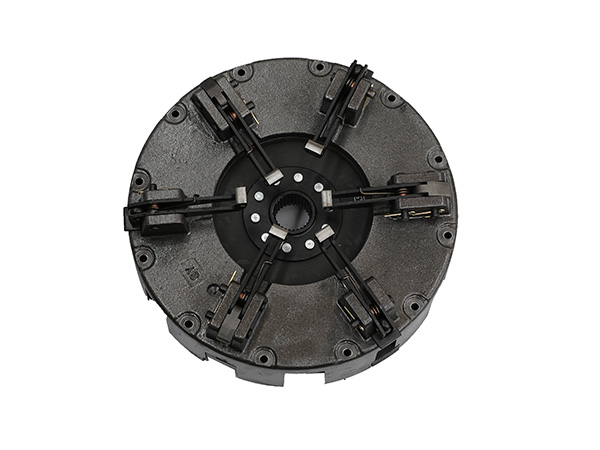

I. Anatomy of a Tractor Clutch

A tractor clutch comprises several key components that work in harmony to facilitate power transfer:

Clutch Pedal: The operator engages and disengages the clutch using the pedal, regulating the power flow between the engine and transmission.

Clutch Plate: Also known as a friction disc, the clutch plate is a high-friction material placed between the pressure plate and the flywheel. It transfers power from the engine to the transmission when engaged.

Pressure Plate: The pressure plate, mounted on the flywheel, applies force to the clutch plate, compressing it against the flywheel when engaged. This pressure allows power transfer to the transmission.

Release Bearing: The release bearing, also known as the throw-out bearing, disengages the clutch when the pedal is depressed. It separates the pressure plate from the clutch plate, interrupting power transmission.

Flywheel: The flywheel is a heavy, rotating disk attached to the engine’s crankshaft. It stores rotational energy and provides a smooth surface for the clutch plate to engage with.

II. Clutch Operation: Engaging and Disengaging

Engagement: When the clutch pedal is released, hydraulic or mechanical force applied to the pressure plate compresses the clutch plate against the flywheel. This connection allows power to flow from the engine to the transmission, enabling the tractor to move.

Disengagement: When the operator depresses the clutch pedal, the release bearing pushes against the pressure plate, creating a gap between the clutch and flywheel. This disengages the engine from the transmission, allowing the tractor to idle without moving.

III. Types of Tractor Clutches

Single Plate Clutch: Common in smaller tractors, this clutch type features a single clutch plate and pressure plate. It is relatively straightforward and easy to operate.

Dual Plate Clutch: Often found in larger, high-performance tractors, dual plate clutches employ two clutch plates and pressure plates. They offer enhanced power handling capabilities and are more suitable for heavy-duty applications.

IV. Maintenance and Troubleshooting

Regular Inspection: Periodically inspect the clutch system for signs of wear, such as slipping, unusual noises, or difficulty engaging gears.

Proper Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and wear. Use the manufacturer-recommended lubricants.

Adjustment: Clutch pedal free play and engagement points may need adjustment over time. Consult the tractor’s manual for specific adjustment procedures.

Replacement: When signs of wear are evident, or if the clutch is slipping, it’s essential to replace worn-out components promptly to prevent further damage to the tractor’s drivetrain.

Conclusion

The tractor clutch, though seemingly unassuming, plays a pivotal role in the efficient operation of agricultural machinery. A thorough understanding of its components, functions, and maintenance requirements empowers tractor operators to ensure optimal performance and longevity. By respecting this vital component, farmers and agricultural professionals can continue to drive their operations forward, plowing the fields of progress and productivity.