A clutch kit is a collection of components designed to replace or upgrade the clutch system in a vehicle. The clutch is an essential part of a manual transmission system that allows the driver to engage or disengage power from the engine to the transmission, enabling gear changes and smooth operation of the vehicle.

A typical clutch kit includes several components that work together to facilitate proper clutch operation. The specific contents of a clutch kit may vary depending on the vehicle make and model, as well as the manufacturer or supplier.

Common components you can find in a clutch kit

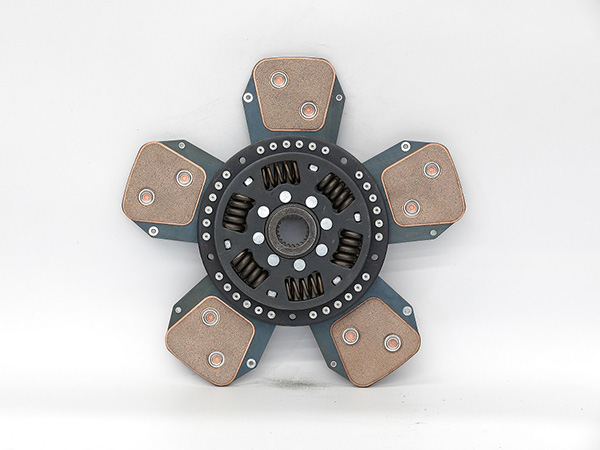

Clutch Disc (Friction Disc): The clutch disc, also known as a friction disc, is a circular plate with friction linings on both sides. It is located between the engine flywheel and the clutch pressure plate. The clutch disc transfers engine torque to the transmission when engaged.

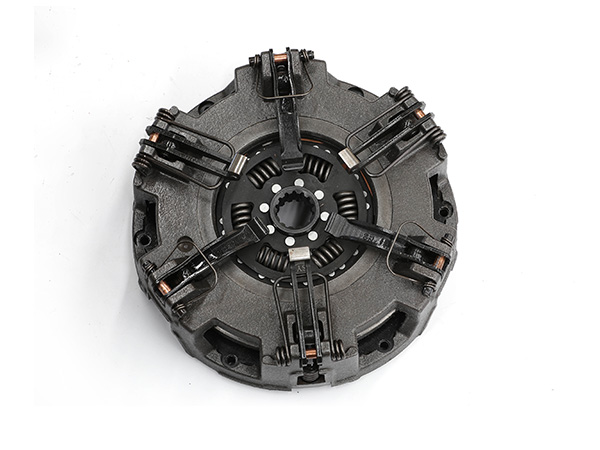

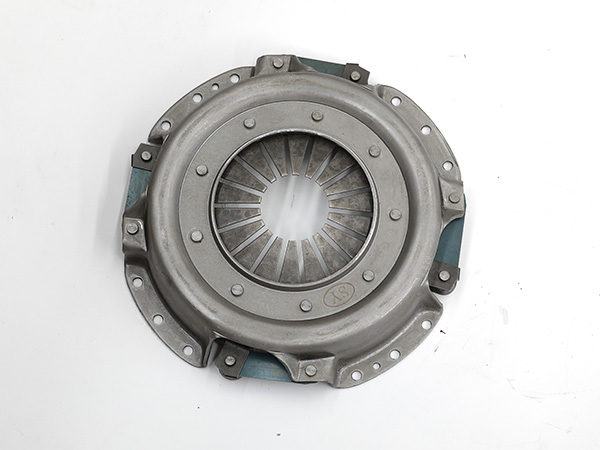

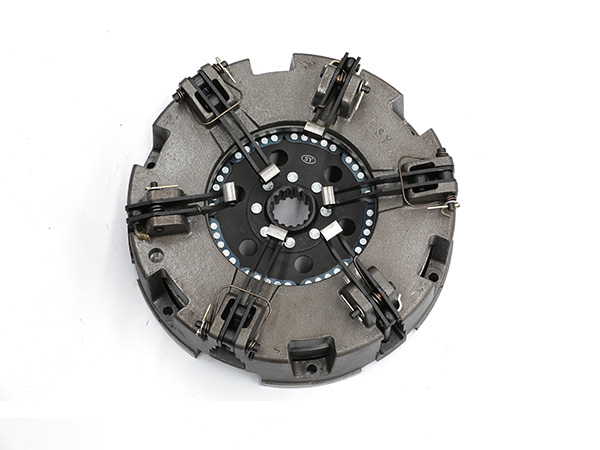

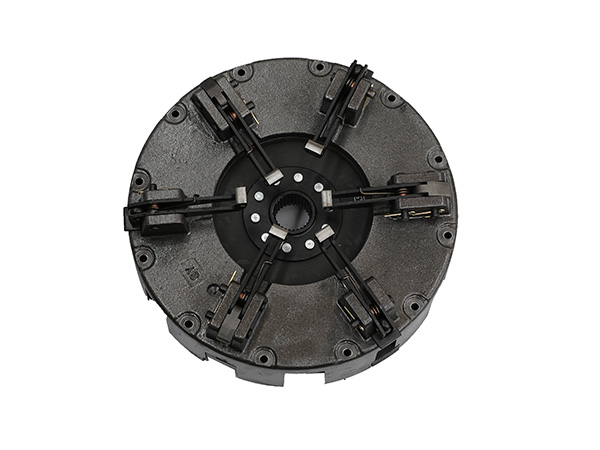

Pressure Plate: The pressure plate is a metal plate that applies pressure to the clutch disc when engaged. It is bolted to the flywheel and exerts force on the clutch disc through a series of springs or a diaphragm mechanism. The pressure plate releases the clutch disc to allow gear changes.

Throwout Bearing (Release Bearing): The throwout bearing, also called a release bearing, is a small bearing that facilitates the engagement and disengagement of the clutch. It pushes against the clutch diaphragm or release fingers when the clutch pedal is depressed, allowing the pressure plate to release the clutch disc.

Pilot Bearing or Bushing: The pilot bearing or bushing is a small bearing located in the center of the flywheel. It supports the transmission input shaft and allows smooth rotation when the clutch is engaged or disengaged.

Alignment Tool: An alignment tool, often included in a clutch kit, is used during the installation process to properly align the clutch disc with the pressure plate and the transmission input shaft. It helps ensure accurate positioning and prevents misalignment issues.

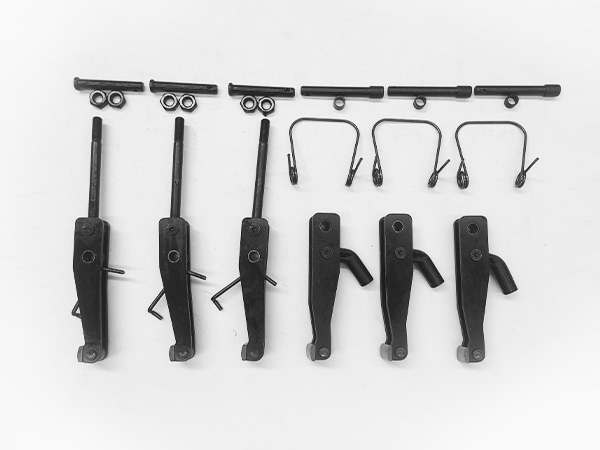

In addition to these core components, a clutch kit may also include other items depending on the specific requirements of the vehicle or the preferences of the user. This can include items such as a clutch release fork, clutch alignment tool, pilot bushing, clutch slave cylinder (in hydraulic systems), or various hardware and fasteners.

Clutch kits are available for different vehicle makes and models, and they can be used for clutch repairs, replacements, or upgrades. It is important to choose a clutch kit that is compatible with the vehicle’s specifications and driving needs to ensure optimal performance and durability.

.jpg)