With the continuous advancement of science and technology, tractors have entered our daily life, and its application is more and more popular with everyone, and the development trend is showing continuous growth. The use of John Deere tractors has a long history, due to the advantages of turbocharged intercooled engines, shifting transmissions, powerful hydraulic systems, safe and applicable driving conditions, stable tractor clutches and reliable service guarantees, etc. Gradually stand out in the field of shredders.

With the rapid development of the economy, China’s agricultural mechanization has entered a stage of vigorous development. Agricultural mechanization is an important symbol of agricultural modernization, and agricultural machinery is an important carrier to realize agricultural mechanization. The level of agricultural machinery and equipment directly affects the level of agricultural mechanization. With the intensification of competition in the agricultural machinery industry, John Deere tractors are favored in my country due to their many leading features.

Advantages of using a John Deere tractor

(1) Equipped with John Deere imported engine

John Deere’s engines generally use turbocharged intercooled engines, which can quickly adapt to load changes and have excellent performance. The control unit of the turbocharged intercooled engine is electronically controlled, which controls the fuel cutoff more accurately, saves the fuel cutoff lever on the instrument panel, and can control the engine through the key. The operation is simple and convenient, and the fuel efficiency is high; High pressure common rail technology reduces fuel consumption and is economical; equipped with dual temperature cooling system, high cooling efficiency, reducing the frequency of abnormal tractor temperature; turbocharged intercooled engine with high rated power, high torque reserve, and high specific resistance It can still easily complete the expected tasks in the soil environment of 10000W It also improves the airflow and filtration efficiency, makes the engine life longer, and is very beneficial to environmental protection.

(2) Shift gearbox

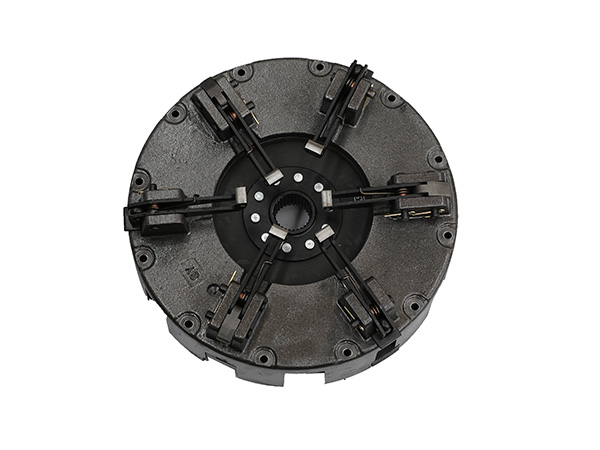

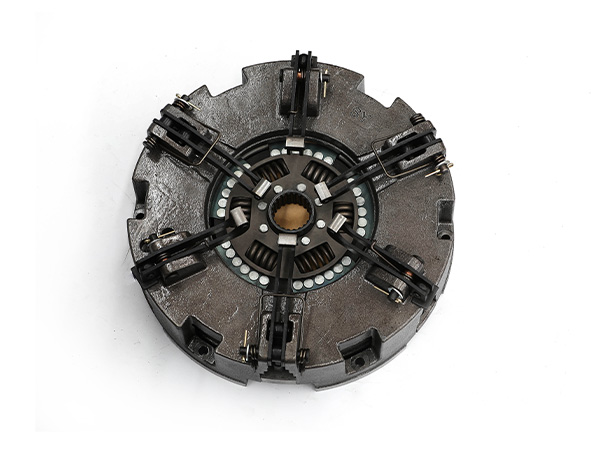

The John Deere tractor adopts a meshing sleeve shift gearbox. With the continuous reform and innovation, the main and auxiliary transmission area has changed from 12 forward gears and 4 reverse gears to 18 forward gears and 6 reverse gears in 2011. This John Deere tractor has the ideal working speed for a variety of field jobs. The agricultural machine operator can choose the appropriate gear according to different operations, different agricultural equipment, changes in vehicle speed, slope of the ground, specific resistance of the working soil, and the size of the traction equipment to meet the needs of different agronomy. Since the meshing sleeve shift gearbox has a double-acting clutch, it does not need to step on the clutch pedal or stop the vehicle to complete the shift within the segment and realize the power reversal. Bring a higher operating experience. The two-speed PTO shaft safety shield ensures safe operation and use. John Deere tractors use an original clutch that lasts the same as a tractor.

(3) Hydraulic system

The John Deere tractor adopts a closed-center pressure and flow compensation hydraulic system. The unique hydraulic system not only allows the John Deere tractor to have higher control accuracy and faster response speed, but also reduces fuel consumption, noise, and more. Large lift force and more accurate implement adjustment. Not only that, but also equipped with two sets of hydraulic output valves as standard, these two sets of output valves can be equipped with hydrostatic power steering and braking according to the needs of the work, so that the entire John Deere tractor can be operated more easily and the braking effect is better. . Due to the existence of the hydraulic oil filter, its high-efficiency filtering ability can keep the hydraulic system clean, improve the working efficiency of the John Deere tractor, and reduce the maintenance cost of the tractor. The position of the oil dipstick of the tractor is reasonable, which is convenient for the farmer to observe the change of the oil level, which avoids the lack of oil during work and reduces the work efficiency.

(4) Safe and applicable driving environment

The appearance of John Deere tractors is high-end and atmospheric, the cab is well sealed, the noise is low, the field of vision of the farmer is wide, and the ergonomic control system is intuitive and easy to understand and easy to operate, providing a more comfortable driving environment for the farmer. The frame of the cab is made of high-strength, low-temperature-resistant steel, and has been certified to national and OECD safety standards. In order to further ensure the safety of agricultural operators, John Deere tractors are also equipped with anti-roll frames and safety belts. The front and rear wheels of the tractor are equipped with large-sized fenders, which can prevent the mud from splashing to the tractor body during operation, ensure the cleanliness of the body, and at the same time, keep the operating environment of the cab clean. The tractor has a transparent baffle, allowing the driver to clearly see the state of the ground. The whole upturned hood is used for easy access to parts, and maintenance and maintenance are simple and fast. The metal tool box is installed on the tractor, which is corrosion-resistant and can be used for a long time. The common tools for maintenance and maintenance are placed in the metal box, which is convenient for timely maintenance when the tractor fails.

Generally, adjustable seats are adopted, and the farm operator can adjust the seat position according to personal preferences to relieve fatigue. The combined instrument panel of the tractor is clear at a glance, and the farmer can observe the real-time status of the vehicle according to the instrument of the tractor, and deal with the alarm information of the vehicle in time. It also has a safety start switch. Only when the driver puts the main transmission lever in the neutral position, the engine can be started, which greatly reduces the machine and personal accidents caused by starting the tractor without removing the gear, and ensures the safe start of the vehicle. The main and auxiliary gear levers are reasonably arranged, the gears are clear and easy to operate. The tractor adopts a hydrostatic braking system with good braking effect. Equipped with air conditioning and heating equipment to ensure the operating comfort of long-term driving. The maintenance and repair of John Deere tractors are also very simple. The cab and protective cover can be opened, and each part can be accessed at close range, which is convenient for inspection and maintenance. The maintenance interval is long, which reduces the user’s cost of use.

(5) Reliable service guarantee

Since the day of Deere’s establishment, honesty, quality, trustworthiness and innovation have been the core values of Deere, and this value concept will never change. With an honest and responsible attitude to customers, John Deere’s factories in China do not use asbestos parts that are harmful to health. Once a component is found or has potential quality problems, Deere will solve the problem for users as soon as possible. . For example, the design of the safety start switch allows the engine to be started only when the main transmission lever is placed in the neutral position, which greatly reduces the machine and personal accidents caused by starting the tractor without removing the gear, and ensures the safe start of the vehicle.

The excellent performance of John Deere products is recognized by users because John Deere has always put high quality throughout all the production processes of tractors to ensure that the equipment can bring high returns to users to the greatest extent. At this stage, the John Deere quality production system is already in the industry-leading stage. For example, the steel used in John Deere tractors are all high-quality steel without cracks and defects, thus ensuring the service life of the tractor.

John Deere tractors have been designing and developing products according to national conditions. The tractors produced are of good quality, high safety, flexible operation, strong adaptability, wide application range, reasonable speed distribution, comfortable driving environment, and good after-sales guarantee. The earth has promoted the development of my country’s agricultural machinery, making my country one step closer to agricultural mechanization.