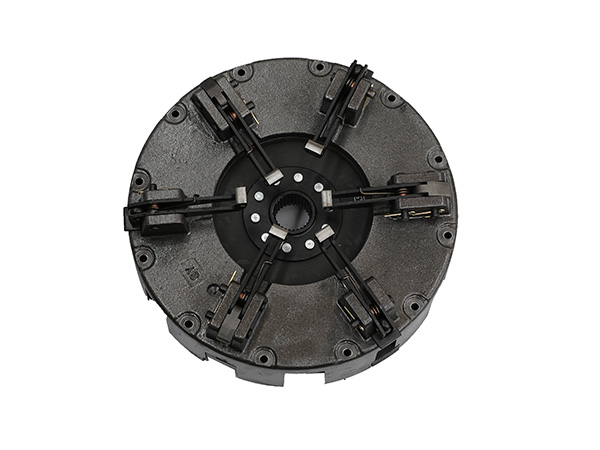

The so-called clutch is to use “off” and “on” to transmit the right amount of power. The clutch consists of a friction plate, a spring plate (the tractor uses a disc spring, and the harvester uses a diaphragm spring), a pressure plate and a power take-off shaft. It is arranged between the engine and the gearbox to transmit the torque stored on the engine flywheel. To the gearbox to ensure that the agricultural machinery transmits the appropriate amount of driving force and torque to the driving wheel under different working conditions.

Clutch is a frequently rubbed part on agricultural machinery (friction plate is a wearing part), it will wear with the increase of use time and frequency, which will cause clutch slip phenomenon.

The clutch is the device that connects the agricultural engine and the transmission, and the clutch pedal is the operating device of the clutch. When the clutch pedal is stepped on or lifted, the engine and the transmission will be temporarily separated or smoothly combined to cut off or transmit power, and realize changes in the movement state of agricultural machinery such as starting, shifting, and parking. Slowly lift the clutch until it is fully lifted. If the engine stalls when the clutch is lifted, it means that the clutch is not slipping. If the engine does not stall when the clutch is lifted, it may be a problem with the clutch.

Features of clutch for agricultural machinery

Tractor clutch: The tractor clutch generally uses a double-acting clutch, that is, one way is responsible for walking, and the other way is responsible for power output. Due to structural reasons, the gap between the flange of the clutch pressure plate and the casing is relatively small, especially when the air humidity is high, and the tractor is not used every day (sometimes out of use for several months), so it is bound to be prone to rust. , The adhesion between the pressure plate bracket and the flange is caused by rust, which leads to the incomplete separation of the clutch.

Suggestion: Before using the tractor that has been parked for a long time, the tractor operator should first open the clutch observation port, use a flat-blade screwdriver to turn the clutch assembly, and spray a little rust remover on the three flanges of the clutch pressure plate, and then step on the A few clutch pedals to move it back and forth, and then use the tractor normally for various tasks.

How to operate the clutch

First, press the pedal firmly with the forefoot of your left foot, and step down or lift the clutch pedal with the flexion and extension of the knee and hip joints. Do not use the toes, soles or heels to step on the clutch pedal to prevent insufficient pedal strength or slip off. pedal. The action of stepping on the clutch pedal should be fast and all the way to the end, so that the clutch can be completely disengaged when the clutch pedal is lifted.

It should be determined according to the manipulation situation. Generally, when the working gear is changed to neutral, the clutch pedal can be lifted quickly. When the agricultural machine starts or shifts, the free stroke before the disengagement is not yet engaged can be slightly faster. When the clutch starts to engage When the clutch is fully engaged, the foot should be quickly removed from the pedal and placed under the pedal. When the clutch is not used in the work of agricultural machinery , Do not put your foot on the clutch pedal, so as not to cause the clutch to have a semi-linked phenomenon, affect the transmission torque, and increase the wear of the parts.

1. Start and shift of agricultural machinery

When starting, depress the clutch to completely disengage; when lifting the clutch pedal, operate according to the essentials of “one fast, two slow, three linkage”. That is, the process of pedal lifting is divided into three stages, starting to lift quickly; when the clutch appears semi-linked (the engine sound changes at this time), the pedal is lifted slightly slower; from the semi-linked to the fully combined process, the pedal is slowly lifted. Lift slowly. When the clutch pedal is raised, gradually step on the accelerator pedal according to the resistance of the engine, so that the agricultural machine can start smoothly. The operation of the throttle should be smooth and appropriate. The clutch pedal operation method of one fast, two slow and three fast should be followed to ensure smooth engagement.

2. Reduce the number of times the clutch is used

If the temperature is too high, the friction lining will be rapidly worn or cracked. Therefore, try to reduce the number of clutch disengagement and engagement, and the number of semi-linkages.

3. In emergency braking or approaching a stop

In the driving of agricultural machinery, do not depress the clutch pedal under any circumstances except for braking at low speed (above 10km/h), which requires depressing the clutch pedal. Depress the clutch and let the farm machine coast down to reduce shock to the engine and driveline.

In order to ensure safety: it is strictly forbidden to work uphill and out of gear, downhill to step on the clutch and slide in neutral gear, and to shift the gear and lift the clutch pedal to start the engine; Wait for the driving wheel to slip.

4. Do not step on the clutch

When the clutch on the agricultural machinery is working normally, it is in a tightly engaged state, and the clutch should not slip. The clutch disengagement is controlled by depressing the clutch pedal. When driving, do not step on the clutch pedal at all times except when the agricultural machinery starts, shifts and brakes at low speed need to step on the clutch pedal.

Stepping on the clutch without incident or putting your foot on the clutch pedal for a long time, the clutch is often engaged, disengaged or semi-slipped, which accelerates the wear of the clutch friction plate and pressure plate, so that the power of the engine cannot be fully transmitted. To drive the wheels, resulting in fuel costs, car costs, and increased driving costs.

Putting the foot on the clutch pedal for a long time during work can easily cause clutch slippage, ablation of the clutch disc, etc. In severe cases, the clutch pressure plate and the end face of the flywheel are ablated and pulled, and the clutch compression spring is annealed.

5. Correct operation when shifting gears

The gearbox of agricultural machinery is generally a meshing sleeve shifting structure. In order to make the shifting smooth and reduce the wear of the shifting mechanism and clutch of the transmission, the “two-leg clutch shifting method” is advocated. That is, when shifting up, depress the clutch pedal and shift the shift lever to a higher gear; when downshifting, depress the clutch pedal while shifting the shift lever to neutral, lift the clutch pedal and increase the speed appropriately according to the vehicle speed. One foot empty, then depress the clutch pedal again while shifting the gear lever into a low gear.

6. Correct use of clutch when braking

In the driving of agricultural machinery, do not depress the clutch pedal under any circumstances except for braking at low speed (above 10km/h), which requires depressing the clutch pedal. Because when the agricultural machinery is braking at medium and high speed, depressing the clutch pedal will not help to improve the braking ability of the agricultural machinery, and will also bring danger to the driving safety.

When braking and stopping at low speed, the purpose of depressing the clutch pedal is only to prevent the engine from stalling. At this time, the correct operation method is to depress the brake pedal first, and then depress the clutch pedal to make the agricultural machine stop smoothly.