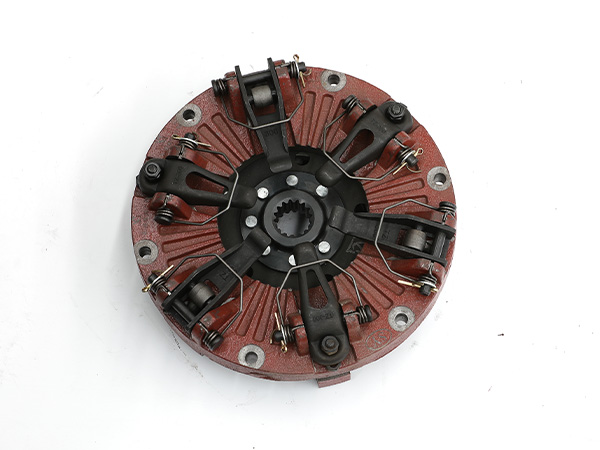

The tractor clutch is installed after the engine and before the transmission. Its basic function is to transmit and cut off the power. The main function is to transmit the power from the engine to the transmission; the second is to ensure that the engine starts and the tractor starts smoothly; Temporary parking; fourth, to prevent overloading of the transmission system; fifth, the double-acting clutch also plays the role of transmitting or cutting off the power output.

However, tractor clutches often fail frequently during use. In fact, among the clutch failures, in addition to the quality problems and design problems of the clutch itself, a large part of the failures are related to improper use and operation. The following tractor clutch manufacturers will give you the details. Introduce the correct operation and use of the tractor clutch.

Do not step on the clutch, do not step on the clutch halfway.

Some tractor operators habitually put their feet on the clutch pedal when working. This habit is not good, and it is easy to damage the clutch. When the clutch of the tractor is working normally, the disc spring tightly presses the friction plate on the flywheel of the engine, and the clutch is in the state of pressing and engaging, and the friction plate does not slip.

When the clutch needs to be disengaged, it is realized by stepping on the clutch pedal. If the tractor is always half-stepped on the clutch, and the foot is placed on the clutch pedal for a long time, the clutch will often be in a semi-engaged and disengaged state, making the clutch It is in a semi-slip state during operation, which accelerates the wear of the clutch friction plate and pressure plate, and reduces the ability of the clutch to transmit torque. It is easy to cause the clutch to slip and burn the friction plate. The end face of the flywheel is ablated and pulled, and the clutch disc spring is annealed. When driving a tractor, you generally do not need to step on the clutch except for starting, shifting and braking at low speed, and you generally do not need to step on the clutch at other times. At this time, do not always step on the clutch pedal.

Correct operation of the tractor when starting.

When the tractor starts, it is necessary to depress the clutch to engage the gear. When depressing the clutch, depress the clutch pedal quickly, and go all the way to the end, so that the clutch can be completely separated, then engage the gear, and then release the clutch pedal; when releasing the clutch pedal, Operate according to the principle of “fast first, then slow”, that is, the free stroke before the clutch is not engaged can be lifted slightly faster, when the clutch starts to engage and appears semi-linked (the engine sound changes at this time), it should stop for a while, and then Slowly lift the clutch pedal (at the same time gradually add the throttle), that is to say, in the process from semi-linked to fully combined, the pedal should be lifted slowly to make the clutch engagement smooth, and while the clutch pedal is slowly lifted, according to the size of the engine resistance Gradually step on the accelerator pedal, the operation of the accelerator should be smooth and appropriate, so that the tractor starts smoothly. After the clutch is fully engaged and the tractor starts smoothly, you should quickly remove your foot from the pedal and place it under the pedal. When the tractor is not using the clutch, it is strictly forbidden to put your foot on the clutch pedal.

Correct operation of the tractor when shifting gears.

At present, the transmission of tractors is still mostly a gear shifting structure with a mesh sleeve. It is recommended to use the two-leg clutch shifting method for shifting, which can make the shifting more smooth and reduce the wear of the shifting mechanism and clutch of the transmission. The specific operation method when using the two-foot clutch to shift gears is as follows: when shifting up, depress the clutch pedal and shift the shift lever to a higher gear; when shifting down, depress the clutch pedal with the first foot and shift the shift lever at the same time. Push to neutral, then lift the clutch pedal, and at the same time give a foot of empty oil according to the speed of the vehicle, so that the engine speed increases, then depress the clutch pedal again, and push the shift lever to the low-speed gear at the same time.

Correct use of the clutch when braking.

In the use of tractors, except for low-speed braking and parking below 10km/h, the clutch pedal is required, and the clutch pedal is generally not required for braking in other situations. When the tractor brakes and stops at low speed, depressing the clutch pedal is mainly to prevent the engine from stalling. At this time, the correct operation method is to depress the brake pedal first, and then depress the clutch pedal to make the tractor stop smoothly; When braking at medium or high speed, depressing the clutch pedal not only does not help braking, but may also bring danger to driving safety.

Pay attention to safety when using the clutch.

It is strictly forbidden to disengage when going uphill; it is strictly forbidden to step on the clutch and slide in neutral when going downhill; it is strictly forbidden to lift the clutch pedal sharply after engaging the gear; The door, the method of slamming the clutch pedal to pass; there is to minimize the number of clutch disengagement and engagement, and the number of semi-linkages during use.

The above is all about the correct use of the tractor clutch. In the process of operating the tractor, you must strictly abide by the correct operating procedures to avoid losses due to improper operation.