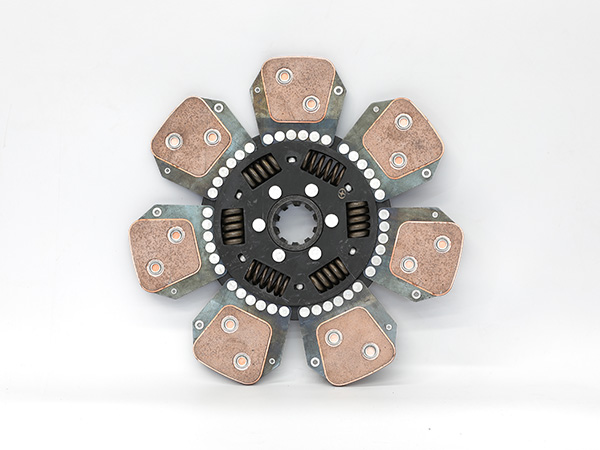

Tractor Clutch Disc

A tractor clutch disc is a component in a tractor clutch system that transfers power from the engine to the transmission. It is typically a circular metal plate with friction material on one side, and is mounted between the pressure plate and flywheel.

When the clutch is engaged, the pressure plate presses the clutch disc against the flywheel, creating friction and transmitting power from the engine to the transmission. When the clutch is disengaged, the pressure plate releases the clutch disc, allowing it to spin freely and disconnecting the engine from the transmission.

A clutch disc is a critical component in a tractor clutch system, and must be properly selected and maintained to ensure reliable and safe operation of the tractor. When selecting a clutch disc, it is important to choose one that is compatible with your specific make and model of tractor, and to follow the manufacturer’s recommendations for installation and maintenance.

Worn or damaged clutch discs can cause slipping, slipping and jerking, or complete failure of the clutch, leading to poor performance, increased wear and tear on other components, and potential safety hazards. Replacing a worn or damaged clutch disc with a high-quality, compatible component can improve the performance and longevity of your tractor and help to ensure that it operates safely and efficiently.

Tractor clutch disc series

Tractor clutch disc material

The material used in tractor clutch discs can vary depending on the application and the specific needs of the equipment. Some of the most common materials used in tractor clutch discs include:

Organic material

This is the most common material used in tractor clutch discs. It is typically made from a mixture of cellulose, resin, and other organic compounds, which are compressed and bonded together to form the disc. Organic clutch discs are known for their smooth engagement and long life, but they can be prone to glazing and overheating under heavy use.

Ceramic material

Ceramic clutch discs are made from a mixture of ceramic fibers and other materials, which are bonded together using heat and pressure. Ceramic clutch discs are known for their high heat resistance and durability, but they can be more expensive than organic discs.

Kevlar material

Kevlar clutch discs are made from a composite material that includes Kevlar fibers and other materials. Kevlar discs are known for their high strength and durability, but they can be more expensive than organic discs.

Metallic material

Metallic clutch discs are made from a combination of metal plates and friction material. They are typically used in heavy-duty applications, such as construction equipment or agricultural machinery, where high torque loads are common.